FAQ

GENERAL

Fiber cement (FC) is a highly durable composite material made from Portland cement, ground sand, cellulose fibre, selected additives and water. It contains no asbestos, glass fibers or formaldehyde. Our products enjoy the benefits of cementitious products (they resist fire, moisture, rotting, insects) while providing the workability and ease of installation compare to wood (they can be nailed and saw cut). They are regarded as being friendly to the environment and are extremely low in maintenance.

Saint-Gobain Prima uses cellulose fibre originated from Radiata Pine species. The fibre is imported from New Zealand. This fibre is identical to the cellulose fire in the paper industry.

No, because cellulose fibre available in Malaysia does not have the required specific property that provide the bending strength of the board.

“Autoclave” is an important process in making FC boards. Essentially, it is a process where “green boards” are fed into curing chamber (like a giant pressure cooker/ steamer). The temperature is kept at 180oC and the pressure is maintained at 8 bars. The entire autoclaving process takes about 16 hours. Upon completion, boards will be fully cured. Under natural condition, cementitious product will take 28 days for full curing.

HANDLING & STORAGE

For boards up to 6mm thick, use Score & Snap knife. Alternatively, use power assisted cutting tool fitted with tungsten carbide tipped/diamond tipped circular saw.

-

- Scoring Knife

-

- Circular Saw

Installation of wet boards is not recommended because upon drying off, boards will likely shrink and cause unsightly appearance on the finished wall. Wet boards will cause delay in board installation progress as they need to be dried before installation.

External boards must be painted as soon as possible after installation. You can use exterior grade water-based quality acrylic paint. Always refer to paint manufacturer for painting instruction. When applied internally, use interior grade water-based paint. In wet area, it is suitable to apply tile over the PRIMA board.

Wood stain finishes are generally formulated to enhance the grain of natural timber products. These coatings are normally available in solvent-based and should not be applied onto FC products. Use only water-based wood stain coating formulated for FC products.

No. Tiles must be applied using flexible tile adhesive manufactured for adhering tiles onto FC board.

YES. The surface needs to be applied with water proofing even though the board is water resistance especially those areas which intend to stick with tiles.

TECHNICAL SUPPORT

Brochures, architectural & BQ specification guidelines, CAD files and installation instructions which are available in either website or hardcopy. Upon request, we also provide typical details tailor-made for specific project needs, commonly referred as “Customised Design Solution” (CDS).

Interested party should submit the relevant information such as artist impression, hand sketches, general details where our products/ systems are intended to be applied.

We do not provide structural calculation on other complementary items such as the design of mild steel frame or light gauge steel frame that support fibre cement application. We also do not provide services related to Profession Engineer (PE) endorsement. Apart from that we do not provide full time on site supervision for running projects.

We provide standard product warranties of up to 3 years. A copy of the warranty can be provided upon request.

BY LAWS & CERTIFICATION

A reference book containing rules/ regulations/ requirements related to construction of buildings. Example – Classification of building material (i.e. Class O, Class 1 to Class 4) is covered in Clause 204.

Yes. PRIMA fibre cement flat sheet is ISO 8336 certified which gives the acceptance of conditions for their use in one or more of the following applications:

- External wall and ceiling finishes

- internal wall and ceiling finishes

- internal and external backing sheets

- Malaysian Standard: MS 1296 – 2010 Fibre-cement flat sheets – Product specification and test methods (First revision)

- Australian Standard: AS/NZS 2908.2

- International Standard Organization: ISO 8336 – Fibre-cement flat sheets

- ASTM International: ASTM 1135

CLASS “O” CERTIFICATE

Under the UBBL Malaysia 1984, Clause 204, a material is classified as meeting the “Class ‘O’ – Surface of no flame spread” requirement if when tested to BS 476 Part 6, has an Index of Performance not exceeding 12 and a subindex (i) not exceeding 6.

It provides a comparative measure (expressed as Fire Propagation Index) of the contribution to the growth of fire made by an essentially flat material, composite or assembly. Best possible result is “0”.

Full description of the standard – BS 476 Fire tests on building materials and structures Part 6. Method of test for fire propagation for products

UBBL states “…… the material of which the wall, ceiling or soffit is constructed, shall comply with the following requirements: Class O. Surface of no flame spread.”

BOMBA. Upon request from manufacturers. SIRIM test reports on the test criteria are required prior to the BOMBA issuance of Class 0.

This certificate serves as evidence which attached to C1/C2/C3 BOMBA forms and to be submitted when applying for CF (certificate of Fitness for Occupation). Without the certificate, the project will be deemed not having the class 0 materials for the respective application, hence CF will be not be issued.

Saint-Gobain Prima’s Technical Department is responsible to fill up the C1 form. C2 and C3 forms must be filled by the contractor and architect respectively.

The following information is required:-

- Project Title

- Saint-Gobain Prima product name/Size/Quantity/Delivery Order

- BOMBA submission reference number

- Name/ Address of the requestor

If required, Saint-Gobain Prima can also assist to fill up C2 & C3 forms but the relevant information must be provided. Nevertheless, the contractor and architect have to sign/ chop at the relevant section, hence the following info has to be obtained:-

- Contractor’s name & Address for C2 form

- Architect’s name & Address for C3 form

Yes. IKRAM is an annually published reference book containing listing of locally manufactured building materials. Being listed in this publication is a pre-requisite for qualifying of a product to be used in government projects. This exercise is in line with the Ministry of Finance’s directive – “Arahan Perbendaharaan (AP) 169.2” forming part of the content of “Surat Pekeliling Perbendaharaan Bil. 7 Tahun 2002”. One can lodge a report to IKRAM if any of the government project site known to have used imported products without consent from MOF.

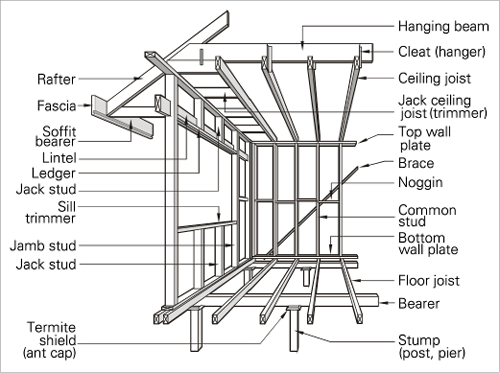

FRAME TERMINOLOGY

PRIMA WALL SYSTEMS

A wall constructed using framing system, clad (on both sides of framework) with lining board. These are the basic component of a ‘drywall’ building system

- Building boards, such as PRIMAflex or PRIMAliner

- Framework constructed using Timber or Steel

- Fixing accessories, screws/ nails, e.t.c.

- For drywall application, we supply PRIMAflex, PRIMAliner & PRIMAplank

-

- Prima Flex

-

- Prima Liner

-

- Prima Plank

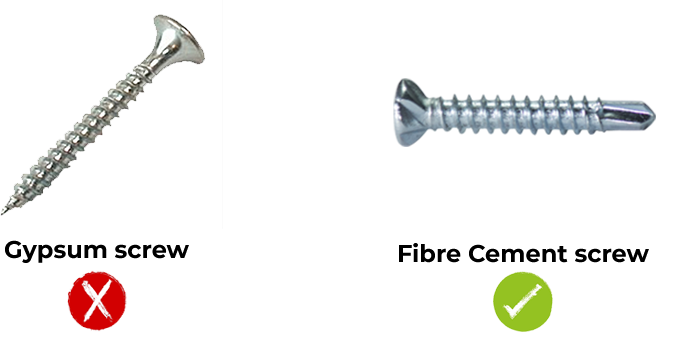

Installation FC boards does not require special screws. In Malaysia, Saint-Gobain Prima supplies PRIMA Self Embedding Head Wing-Tek screw as part of the accessories.

PRIMA Fastener S.E.H Wing-Tek Screw

No. These screws were not designed for fixing FC boards. The screw head is smooth and not equipped with ‘serration’ (sharp saw-like ribs). Thus, screw heads will not flush properly with the board surface or embedded in the FC board.

Yes. Please consult Saint-Gobain Prima for recommended specification to meet the required performance.

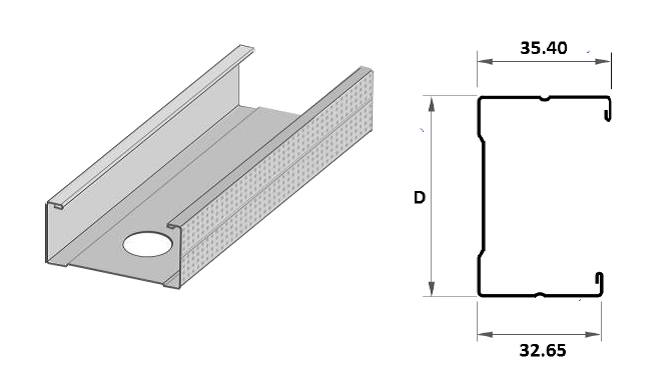

-

- Prima C-Studs

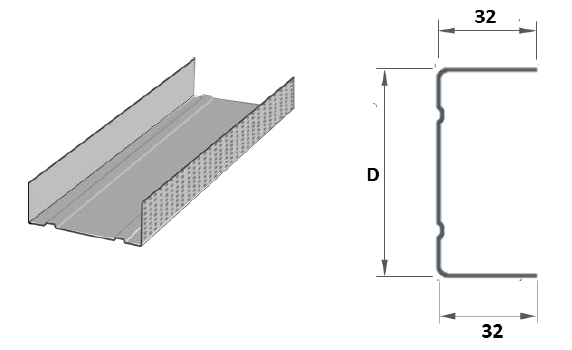

-

- Prima U-Track

- Hammer for driving nails (fixing to timber frame)

- Power assisted screw driver (fixing to steel frame). Manual fixing is not recommended.

Use Polyurethane (PU) or Modifies Silicon (MS) sealant that is compatible with cementitious products. Sealant must be flexible and paintable.

You can use PRIMA Jointing Compound Plus that supplied by Saint-Gobain Prima. The compound has a natural cementitious component which is compatible with fibre cement boards. It is not preferable to use gypsum based compound for flush jointing process.

PRIMA Jointing Compound Plus

IBS

IBS refers to building systems that have the following attributes:-

(These are the principles on IBS Score)

- Prefabrication and pre-cast components

- Off-site production

- Standardized component (open building system)

- Repeatability

- Modular coordination concept; MS1064

- Structural system – 50%

- Wall system – 20%

- Other simplified saving construction solution – 30%

Objectives:

- Reduce labour dependency

- Value for money

- Consistent quality

- Speed

Yes – We offer 2 types of wall systems, PRIMA Drywall & Solidwall.

Saint-Gobain Prima IBS wall systems have an IBS factor of 1.0. Maximum possible score for wall element is 20 points. Assuming 70% of the total wall area is fabricated using PRIMA IBS System, the IBS score would be calculated as follows –

= IBS factor x Max. possible score x % of wall area using PRIMA IBS

= 1.0 x 20 points x 70% usage —- 14 points

Example of IBS wall systems include – masonry block work (IBS factor = 0.5), pre-cast concrete panel (IBS factor = 1), other drywall solutions such as gypsum board drywall (IBS factor = 1). For more information can contact CIDB IBS Centre.

Construction Industry Development Board (CIDB) Malaysia.

RISP is an initiative by JKR (Specialised Services Div., Civil, Structural and Bridge Engineering Branch) to register IBS suppliers that involved in manufacturing & supplying structural building components such as beams, columns and floor slabs. It is an additional registration requirement for government jobs.

No. We only supply non-structural wall systems, also known as non-load bearing wall.

OTHERS

INSTALLATION VIDEOS